5 Surprising Ways To Use Duraspin Auto-Feed Screw Drivers

DURASPIN is known as the best-in-class auto-feed screw driver for fast and efficient drywalling, subflooring, decking and fence building. However, thanks to its versatility and durability, DURASPIN is also ideal for many types of commercial and manufacturing tasks.

The benefits of DURASPIN — one-handed operation, no dropped screws, precise screw

placement, and more — create a big productivity boost on any job that requires a high volume of screws to be attached quickly and accurately. Additionally, SENCO offers more than 40 types of collated, self-tapping screws optimized for use in DURASPIN tools, for just about every job and material, including wood, composite and heavy steel.

Here are some of the unique ways our customers use DURASPIN off the construction site.

LEARN MORE

Pallet And Crate Assembly

Pallets and crates are an incredibly important part of the supply chain. Billions of them are in circulation right now, and almost every product you purchase — from groceries to large appliances — are shipped, delivered and stored on or in these simple structures. Most are made from good, old-fashioned wood, which is where DURASPIN excels.

A DS322-18V can drive screws up to three inches long, easily attaching pallet deckboards to runners, and crate walls to rails. Screws provide superior fastening power and make it easier to remove and repair broken boards. While DURASPIN is useful during mass production of pallets and crates, it is also useful on other types of production lines. A D322-18V system is a must-have in any manufacturing operation where large or custom-made goods have to be crated up prior to shipping, or where pallets routinely need to be repaired.

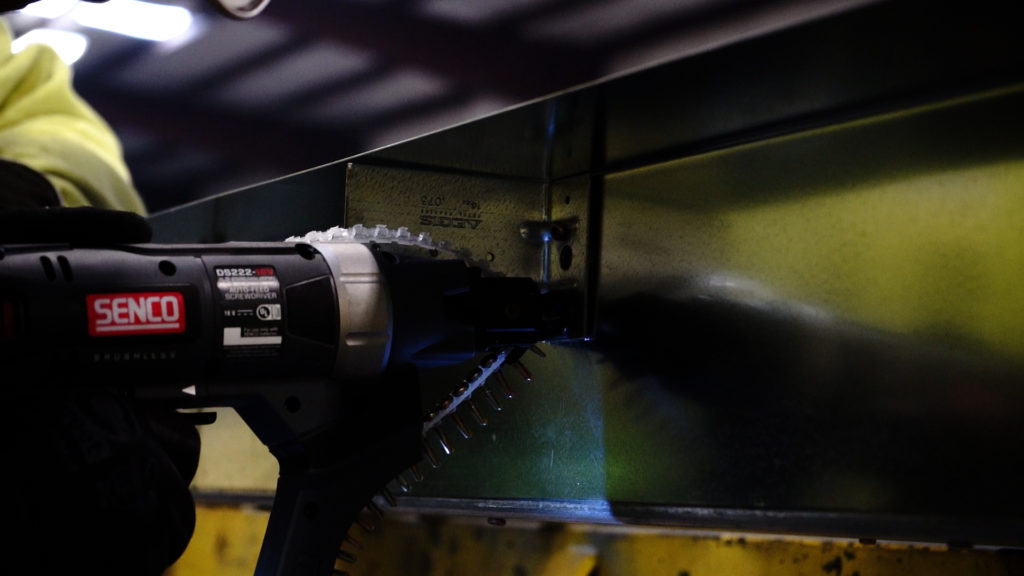

Enclosed Trailers

Building an enclosed cargo trailer isn’t so different from constructing a building. First, the frame

is fabricated, typically from metal. Then flooring, interior walls and exterior skins are attached.

Flooring is typically made of wood or wood composite. Interior walls are a thin wood composite

and the exterior skins are typically sheet metal.

The DS222-18V is a low-speed, high-torque system engineered for fast metal-to-metal or wood-to-metal applications. With it, a good installer can securely attach walls and floors to a steel trailer frame in just a few minutes. Such trailers are often used to haul tools to construction sites, meaning DURASPIN systems will travel in trailers that DURASPIN systems built. It’s the circle of life!

Campers and RVs

Building a camper or recreational vehicle is even more similar to traditional construction. Not

only do campers start with a wood or metal frame, flooring and siding, but there are windows,

doors, ventilation, plumbing, electrical systems and built-in furniture, much of which is installed

by hand on site. Any one of those processes can be sped up with DURASPIN.

All DURASPIN screw drivers — high- and low-speed systems, as well as systems that drive 2-

and 3-inch screws — have a wide range of uses in camper assembly. A few DURASPINs and

SENCO’s wide range of collated screws make short work of attaching plywood roofs, subfloor,

gutter rails and roof accessories such as skylights and vent pipes, as well as assembling

cabinets and furniture and attaching wood, metal, or fiberglass wall coverings.

BROWSE DURASPIN INTEGRATED SYSTEMS

Offsite Construction

Offsite construction — also known as prefabrication or panelized construction — is a growing

industry that has changed the way structures are built. Rather than stick framing from top to

bottom on site, certain elements such as walls and trusses can be assembled on a

manufacturing line and transported to the build location. This offers a wide range of benefits,

including faster builds, cost savings and improved site safety.

In controlled prefabrication environments, DURASPIN is even faster and more accurate than on

a traditional jobsite. For examples, walls, floors or metal trusses can be laid flat, allowing the

user to quickly attach drywall or plywood without climbing on and off a ladder. DURASPIN

attachments quickly and easily attach to popular brands of screw guns, providing a cost-

effective upgrade for offsite construction crews.

Automation

Want to achieve even greater throughput and more consistent quality? DURASPIN systems can

be used with automated screw machines for faster speed and better consistency in a true mass

production setting. Whether you’re building pallets or attaching gypsum to metal frames, there is

no shortage of innovative ways to use your DURASPIN system.